CaskDefence is a premier manufacturer of high-precision ammunition components for small arms (e.g., 5.56mm, 7.62mm, 9mm, .50 BMG) and large caliber artillery systems (155mm, 122mm). Our products, often produced using CaskDefence's own Component Making Machines, are engineered to meet stringent NATO, MIL-SPEC, SAAMI, and CIP quality standards, ensuring unparalleled reliability, consistency, and superior terminal performance in the field for diverse operational needs, from training ranges to active combat zones.

Inquire About ComponentsCaskDefence ammunition components are foundational to the reliable performance of a wide array of ammunition types used by military, law enforcement, and security organizations worldwide. Our commitment to precision ensures these components meet the demands of various operational scenarios.

Our components (casings, primers, cores, jackets) are used to manufacture standard ball ammunition for rifles and machine guns (e.g., 5.56mm M193/M855, 7.62mm M80), armor-piercing (AP) rounds (e.g., M855A1, M993), tracer rounds, and specialized sniper ammunition. Performance is critical for infantry engagements, vehicle-mounted weapons, and special operations in diverse environments from arctic cold to desert heat.

Components for manufacturing handgun ammunition (e.g., 9mm, .40 S&W, .45 ACP) used for duty, training, and tactical operations. This includes frangible rounds for reduced ricochet in training or CQB, and hollow-point projectiles for controlled expansion. Reliability is paramount for officer safety and mission success in urban environments or critical infrastructure protection.

Precision-forged projectile bodies, fuze components, and rotating bands for 155mm (e.g., M107 HE, M795 HE) and 122mm artillery systems. Essential for providing indirect fire support, area denial, and counter-battery fire in conventional warfare scenarios. Components must withstand extreme launch pressures and maintain aerodynamic stability for long-range accuracy in varied terrain and weather.

Supplying components to national arsenals and Original Equipment Manufacturers (OEMs) globally, supporting their sovereign ammunition production capabilities. This ensures consistent quality and adherence to specific national or NATO/MIL-SPEC standards. CaskDefence Component Making Machines are often part of these turnkey solutions.

Components for less-lethal ammunition, breaching rounds, and specialized effectors for unmanned systems. The adaptability of our manufacturing processes allows for custom component design for unique defense requirements, often developed in collaboration with our Special Design Unit.

Manufacturing components for cost-effective training ammunition, including blank rounds and rounds with reduced hazard (e.g., frangible projectiles). Consistency in training ammunition components ensures realistic weapon function and safety on the range, critical for maintaining operator proficiency across different weapon systems.

CaskDefence manufactures a comprehensive range of bullet components, meticulously engineered for consistent performance, accuracy, and terminal effectiveness. Our commitment to quality, supported by advanced manufacturing like our Component Making Machines, ensures each component meets the rigorous demands of military, law enforcement, and sporting applications.

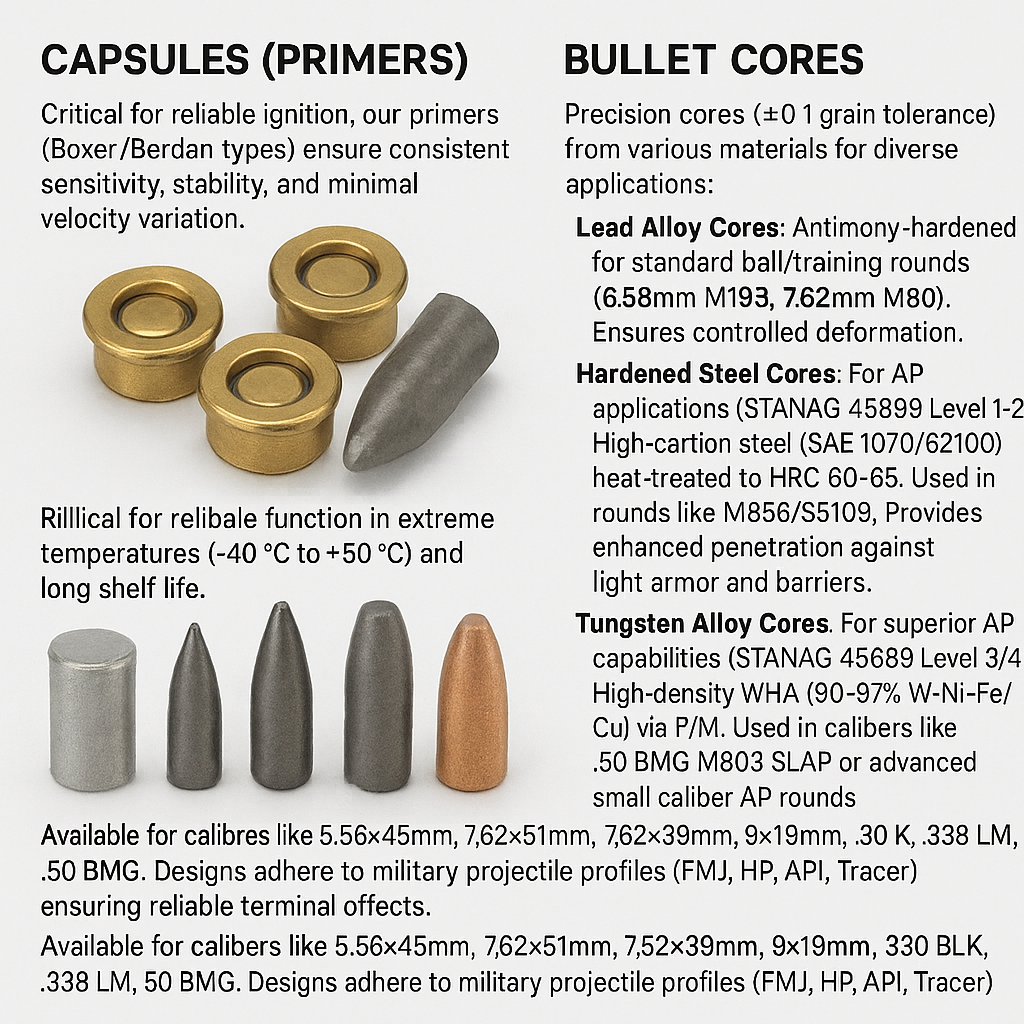

Critical for reliable ignition, our primers (Boxer/Berdan types) ensure consistent sensitivity, stability, and minimal velocity variation. Non-corrosive, non-mercuric compounds (e.g., lead styphnate based) in high-grade brass cups (Alloy C26000) adhere to NATO (STANAG 4172), SAAMI, and CIP specifications. Benefits include reliable function in extreme temperatures (-40°C to +60°C) and long shelf life.

Precision cores (±0.1 grain tolerance) from various materials for diverse applications:

Available for calibers like 5.56x45mm, 7.62x51mm, 7.62x39mm, 9x19mm, .300 BLK, .338 LM, .50 BMG. Designs adhere to military projectile profiles (FMJ, HP, API, Tracer) ensuring reliable terminal effects.

Ensure proper chambering, obturation, and reliable extraction. Manufactured from high-quality cartridge brass (70/30 CuZn Alloy C26000) or precision-drawn coated steel through multi-stage press drawing, annealing, and forming. Strict QC (dimensional checks, material integrity, pressure resistance) guarantees consistency for superior ballistic uniformity and safety. Primer pockets held to tight tolerances for reliable primer seating. Advantage of CaskDefence casings: consistent case volume ensuring repeatable propellant burn and muzzle velocities.

Precision-drawn jackets from gilding metal (95/5 or 90/10 CuZn), copper, or steel for projectile integrity, aerodynamic stability, and barrel protection. Controlled wall thickness and concentricity (<0.03mm TIR) ensure optimal bullet assembly and aerodynamic performance (consistent BC). Benefits include reduced barrel wear and predictable trajectory. Essential for FMJ, HP, SP, Tracer designs.

CaskDefence produces critical components for 155mm (M107, M795 HE, M549 RAP) and 122mm (OF-29 HE, D-30/2S1 types) artillery systems, engineered for precision, reliability, and safety under high chamber pressures (up to 600 MPa) and diverse environmental conditions. Manufacturing precision using our advanced Component Making Machines and quality control is paramount for accurate long-range fire missions, from the Arctic to desert environments.

Adherence to strict material specs (chemical composition, mechanical properties) and manufacturing tolerances (±0.05mm or tighter). Advanced metallurgical processes, NDT (ultrasonic, MPI, X-ray), and comprehensive QC ensure performance under extreme pressures and battlefield conditions (MIL-STD-810G). Full material traceability. Benefit: Unwavering reliability and safety for artillery crews and predictable performance for fire missions across all climates and terrains.

CaskDefence's commitment to quality is unwavering. Our ammunition components are manufactured in ISO 9001:2015 certified facilities, leveraging our advanced Component Making Machines and adhering to NATO STANAGs, MIL-SPEC, SAAMI/CIP standards. Our QA processes ensure dimensional accuracy, material integrity, and functional performance critical for defense applications.

State-of-the-art CMMs, optical comparators, laser micrometers ensure precise dimensional accuracy (microns/tenths of mm). Statistical Process Control (SPC) monitors and controls production, preventing deviations. This precision translates to more consistent ballistic performance and reliability in extreme conditions, such as high-altitude firing or humid coastal environments.

Comprehensive NDT (X-ray, ultrasonic, eddy current, MPI) and destructive lot acceptance testing (pressure testing, hardness, microstructural analysis, ballistic performance) are strictly enforced. This ensures components function reliably under the stresses of automatic weapon fire or high-G artillery launches.

Complete traceability of raw materials and manufacturing processes. Strict adherence to safety, environmental, and export control regulations (ITAR, EAR). This ensures accountability and supports lifecycle management, critical for military and security end-users.

Our dedication to precision engineering and robust quality control ensures that CaskDefence ammunition components deliver unparalleled reliability and performance for critical defense applications worldwide, directly contributing to mission success and operator safety in any operational theatre.

Ensure the reliability and performance of your ammunition systems with CaskDefence components. Contact our specialists to discuss your specific caliber requirements, technical specifications, and volume needs. Leverage our expertise, potentially including our advanced Component Making Machines for your own production, to achieve superior results.

Request Component Quotation