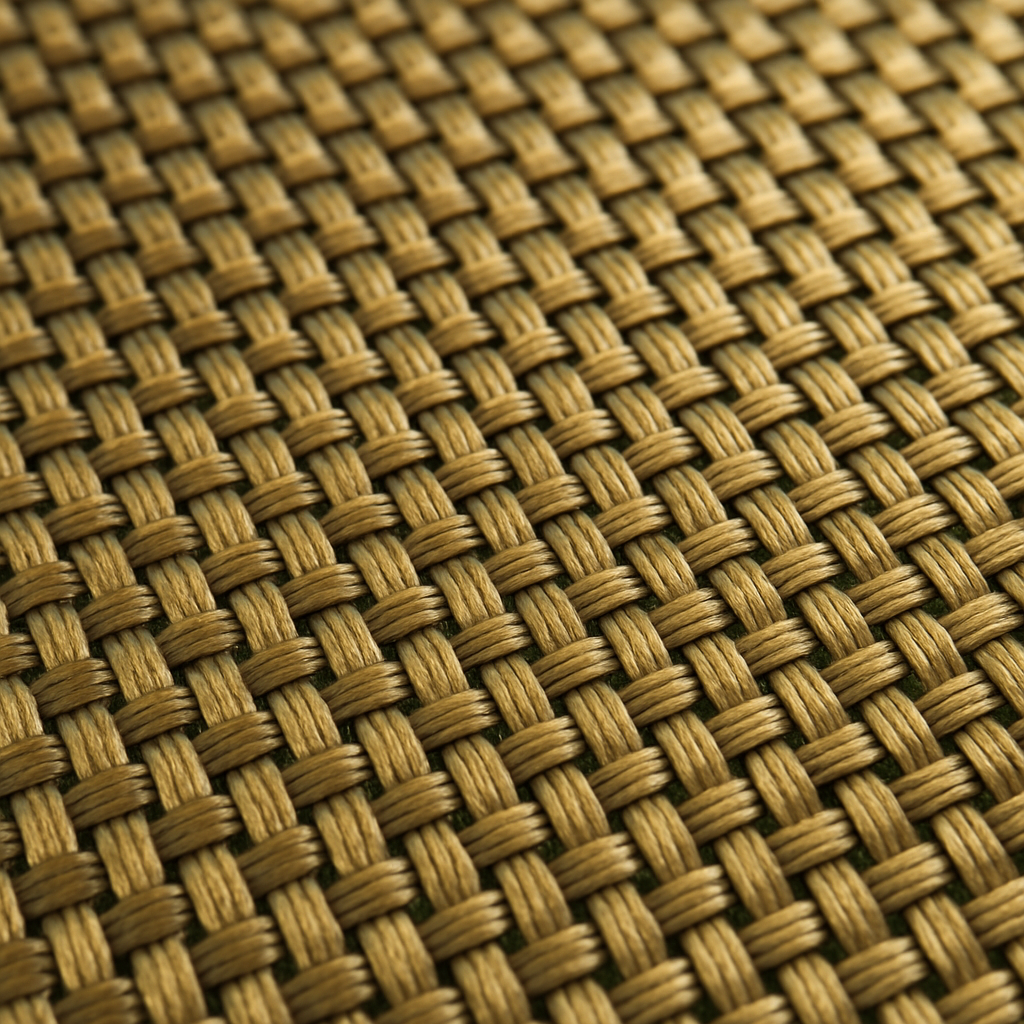

CaskDefence provides premium-grade woven Kevlar® (e.g., K29, KM2 Plus) and other aramid fiber fabrics (e.g., Twaron®), forming a critical material foundation for superior ballistic, fragmentation, and stab protection. Our fabrics are engineered for exceptional performance and reliability under extreme conditions, serving as a core component in life-saving protective systems including our own tactical helmets and bulletproof vests, and utilized by our Special Design Unit for bespoke armor solutions.

Inquire About Ballistic Fabric Supply

Our woven Kevlar® and aramid fiber fabrics are key materials in modern protective solutions, renowned for their exceptional properties. These offer significant advantages over conventional materials for ballistic, fragmentation, stab, and mechanical protection, making them indispensable for applications ranging from personal body armor in urban combat to spall liners in armored vehicles operating in high-threat desert environments.

Aramid fibers like Kevlar® (e.g., KM2 Plus: tensile strength ~3.6 GPa, density ~1.44 g/cm³) are ~5x stronger than steel by weight. This allows for lightweight, flexible protective gear (helmets, vests) with incredible stopping power, enhancing operator mobility and reducing fatigue during extended missions or rapid deployments. Comparative Benefit: Lighter armor solutions mean increased agility and endurance for the wearer compared to steel-based systems offering similar protection.

The unique molecular structure (long, rigid polymer chains, strong intermolecular hydrogen bonds) and optimized weaving patterns (plain, basket, twill) enable multi-layered aramid fabric systems to effectively absorb and dissipate projectile/fragment energy through yarn stress/strain, pull-out/friction, tensile failure, and delamination. This prevents penetration and minimizes behind-armor blunt trauma (BABT). Performance measured by V50 (STANAG 2920) and V0 (NIJ 0101.06). Benefit: Superior protection against a wide range of threats encountered in diverse operational scenarios, from handgun rounds in close-quarters to IED fragments in asymmetric warfare.

Beyond ballistics, aramid fabrics offer excellent inherent resistance to cuts (EN 388 levels), punctures (NIJ 0115.00 for stab resistance), and abrasion. This durability is crucial for protective apparel in industrial settings (e.g., handling sharp materials) and for maintaining the integrity of ballistic protection in harsh field conditions (e.g., crawling over rough terrain, impacts from debris).

Kevlar® and similar aramid fibers exhibit robust resistance to organic solvents, fuels, lubricants, and many corrosive agents. They maintain structural integrity and protective properties across a broad temperature spectrum (approx. -196°C to +204°C continuous use), vital in extreme climates (arctic cold, desert heat) or exposure to heat sources without melting or significant degradation. Benefit: Reliable performance in chemically aggressive environments or areas with extreme temperature fluctuations.

Aramid fibers are known for durability, fatigue resistance, and impact damage resistance. Low creep ensures protective equipment maintains size, shape, and coverage. Excellent dimensional stability (low shrinkage/expansion with temperature/humidity) ensures consistent protective capabilities over extended use and storage. Benefit: Longer service life and consistent protection across varied environmental conditions, reducing lifecycle costs.

Our woven Kevlar® and aramid fabrics are produced using advanced manufacturing processes and stringent quality controls to ensure consistent quality, optimal ballistic performance, and adherence to exacting specifications for denier, yarn count, areal density, weave integrity, and finish. This precision is key to the reliable performance of CaskDefence protective products.

State-of-the-art looms and proprietary weaving methodologies for high-performance technical textiles. We create specific fabric constructions (Plain, Twill, Satin, Basket, Ripstop) with controlled thread counts (EPI/PPI) optimized for energy absorption. Yarn properties (Kevlar® K29, KM2 Plus; Twaron® 1000/2000), denier (400D-3000D), and crimp are meticulously controlled to achieve desired areal densities (200-700+ g/m²), thickness, flexibility, and ballistic performance. Benefit: Consistent fabric structure translates to reliable and predictable protection levels.

Precise yarn tension control throughout warping and weaving. In-line monitoring for defects. Post-production QC verifies areal density (ASTM D3776), weave integrity, thickness (ASTM D1777), tensile strength (ASTM D5035), tear strength (ASTM D2261), and dimensional stability. SPC ensures lot-to-lot consistency, vital for reliable ballistic performance in body armor and helmets intended for use in life-threatening situations.

Water-repellent coatings (DWR) to prevent moisture absorption (critical for maintaining performance in wet or humid environments like jungles or maritime operations). Flame-retardant applications (FAR 25.853, NFPA 1971). UV inhibitors for protection against sunlight degradation. Resin impregnation (prepregging) for rigid composite panels (helmets, hard armor plates). Benefit: Enhanced performance and durability tailored to specific operational environments and end-product requirements.

Woven Kevlar® and aramid fabrics from CaskDefence are versatile, high-performance materials critical to numerous defense, security, and industrial applications globally. Their unique properties make them essential components in modern protective systems, from personal body armor used by special forces to spall liners in heavy armored vehicles.

Core ballistic layer in CaskDefence bulletproof vests (NIJ II-IIIA), tactical vests, EOD suits. Offers protection against handgun rounds and fragmentation while remaining lightweight and flexible for operations in urban terrains or for extended wear during patrols. Interconnection: Directly used in CaskDefence vest products.

Integrated layers of woven aramid prepreg form rigid shells for CaskDefence tactical helmets (PASGT, ACH, FAST styles). Provides NIJ IIIA ballistic and high V50 fragmentation protection, critical for head safety in combat or riot control scenarios. Interconnection: Directly used in CaskDefence helmet products.

Lightweight spall liners for armored vehicles (APCs, IFVs, MRAPs) catch secondary fragments from interior armor upon projectile impact, significantly reducing occupant injury. Performance critical in IED-laden environments. Interconnection: Can be part of SDU custom vehicle armor projects.

Heavyweight woven aramid fabrics for flexible, high-strength blast containment blankets and curtains used by EOD personnel and in demining operations to mitigate blast pressure and contain fragments from explosive devices, crucial for checkpoint security or sensitive site protection.

Ballistic panels and curtain systems for reinforcing military installations, checkpoints, embassies, and safe rooms against small arms fire and fragmentation, providing enhanced protection for personnel in fixed or temporary structures.

Used in anti-piracy curtains, lightweight armor for patrol boats/RIBs, and specialized PPE for maritime security, maintaining performance in wet environments. Essential for protecting crews and critical systems on vessels operating in high-risk waters.

Lightweight ballistic protection in aircraft cockpits, shielding for critical components (fuel tanks, avionics) against ground fire/fragmentation, and engine containment rings. Its strength-to-weight ratio is invaluable for minimizing aircraft weight while maximizing protection.

Development of anti-stab vests (NIJ 0115.00), demining aprons, protective coverings for sensitive equipment, and reinforcement in high-performance sporting goods. Interconnection: The Special Design Unit leverages this material for highly customized protective solutions based on unique threat assessments.

Partner with CaskDefence for your supply of premium woven Kevlar® and aramid fabrics. Our technical team can assist in selecting optimal fabric specifications (fiber type, denier, weave, areal density, finishes) for your protective application. Ensure your products, like our helmets and vests, benefit from the best material foundation. Contact us for datasheets, samples, and quotations.

Request Fabric Information